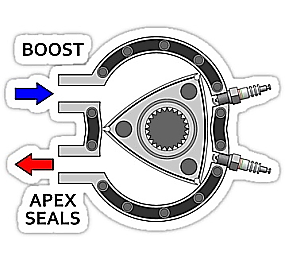

Compare the REST below........................................ buyer Be Ware !!!!!!!!!

What follows some viewers may find disturbing!

Not for the weak or people on medication, if you are an unfortunate victim who has been hyped up to buy these poor products listed below you may want to consult with your

doctor as what you will see may cause an adverse reaction to your health or state of mind !

When you pay peanuts you get this made by MONKEYS! When you pay peanuts you get this made by MONKEYS!

ka-POW! ka-POW!

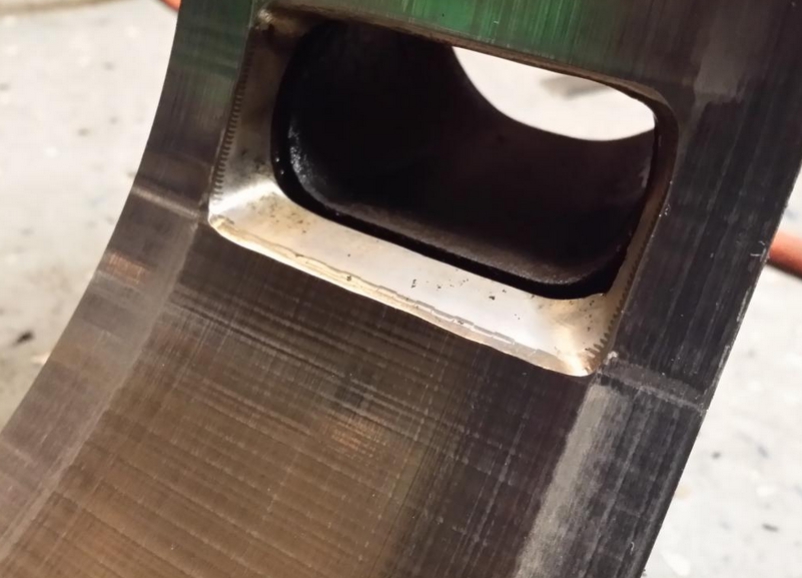

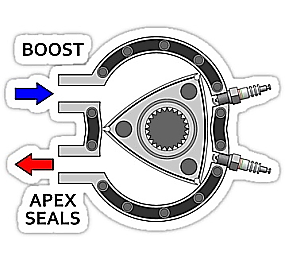

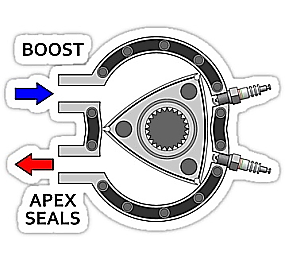

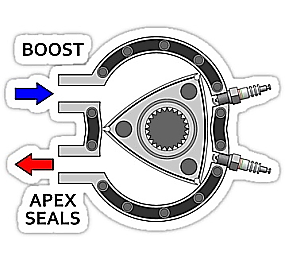

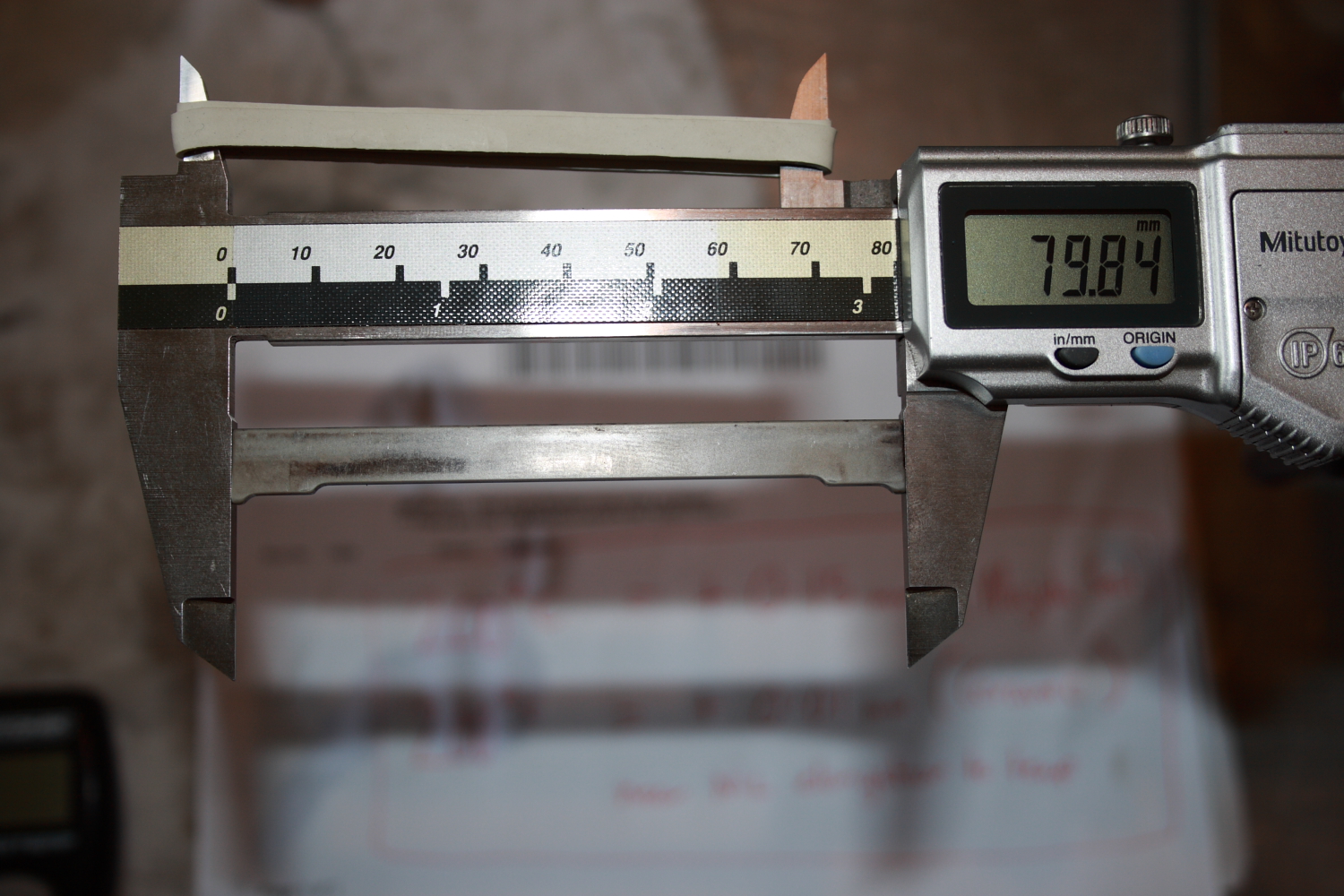

ground on a taper!, bottom of it is 1.932mm and top is 1.945mm

OVER 0.013mm deviation in thickness in only 8mm distance!

is this taking the piss or what? and people pay money for this.... OMG!

BRAVO!!! It's 'special' to make something that will:

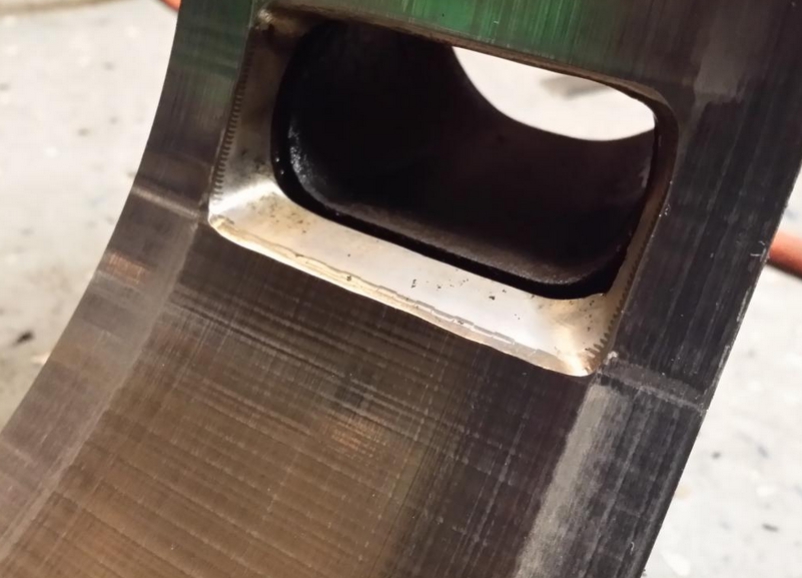

* Snap in half with little effort (see pic)

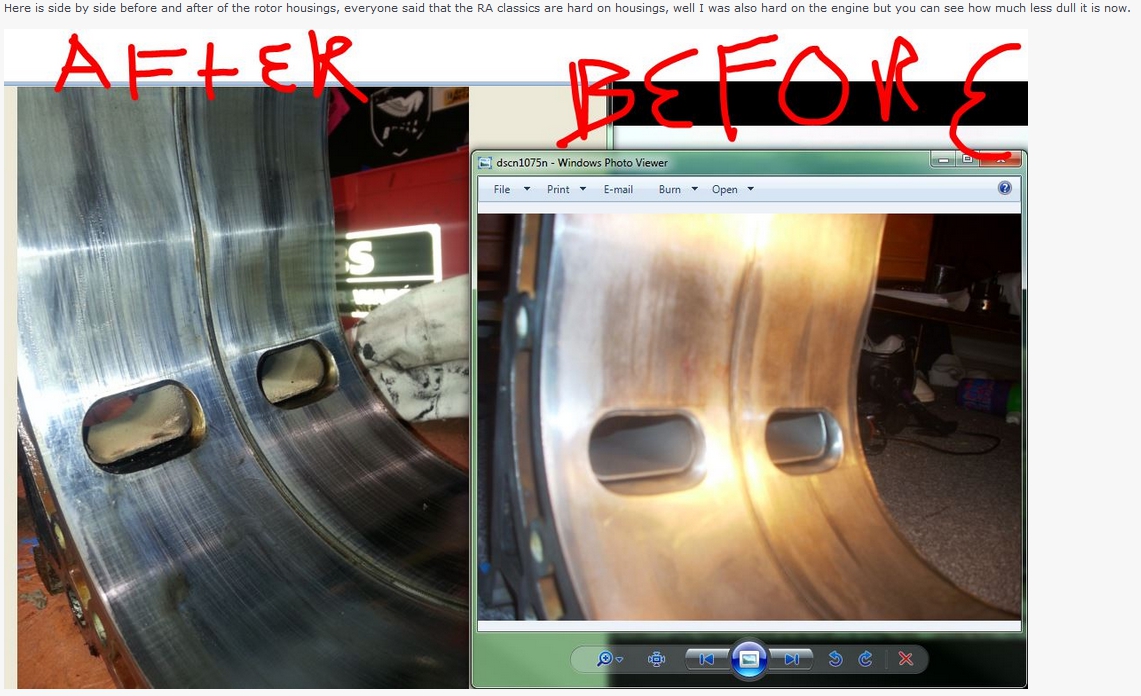

* Rape rotor housings (material miss match)

* And be made in such a bad way (poor manufacturing)

fragile, wrong material, and incorrectly made! #1 turd burger, suitable only for a 6 second OIL SMOKE MACHINE

ALL of these alternatives RAPE! ROTOR HOUSINGS

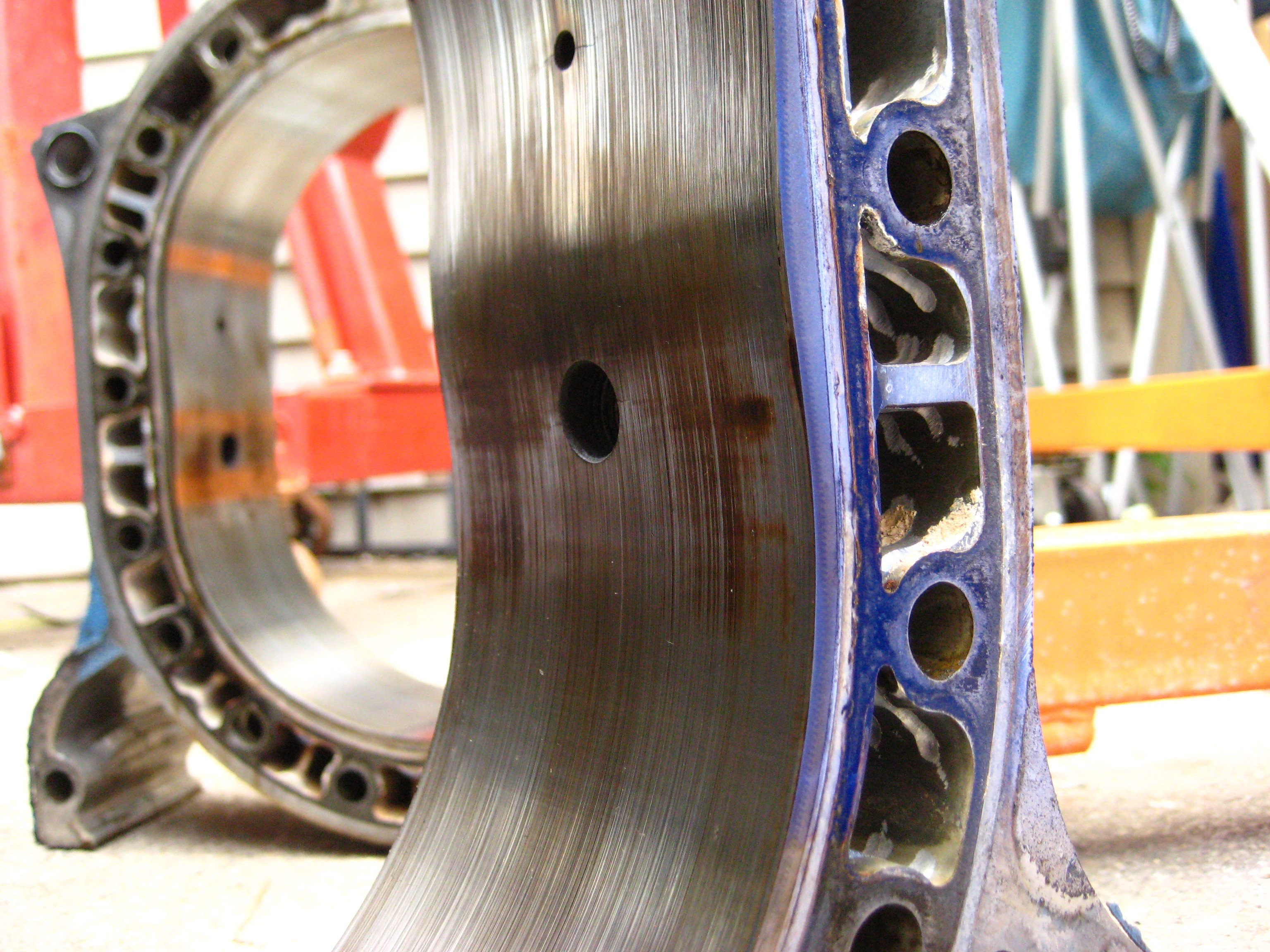

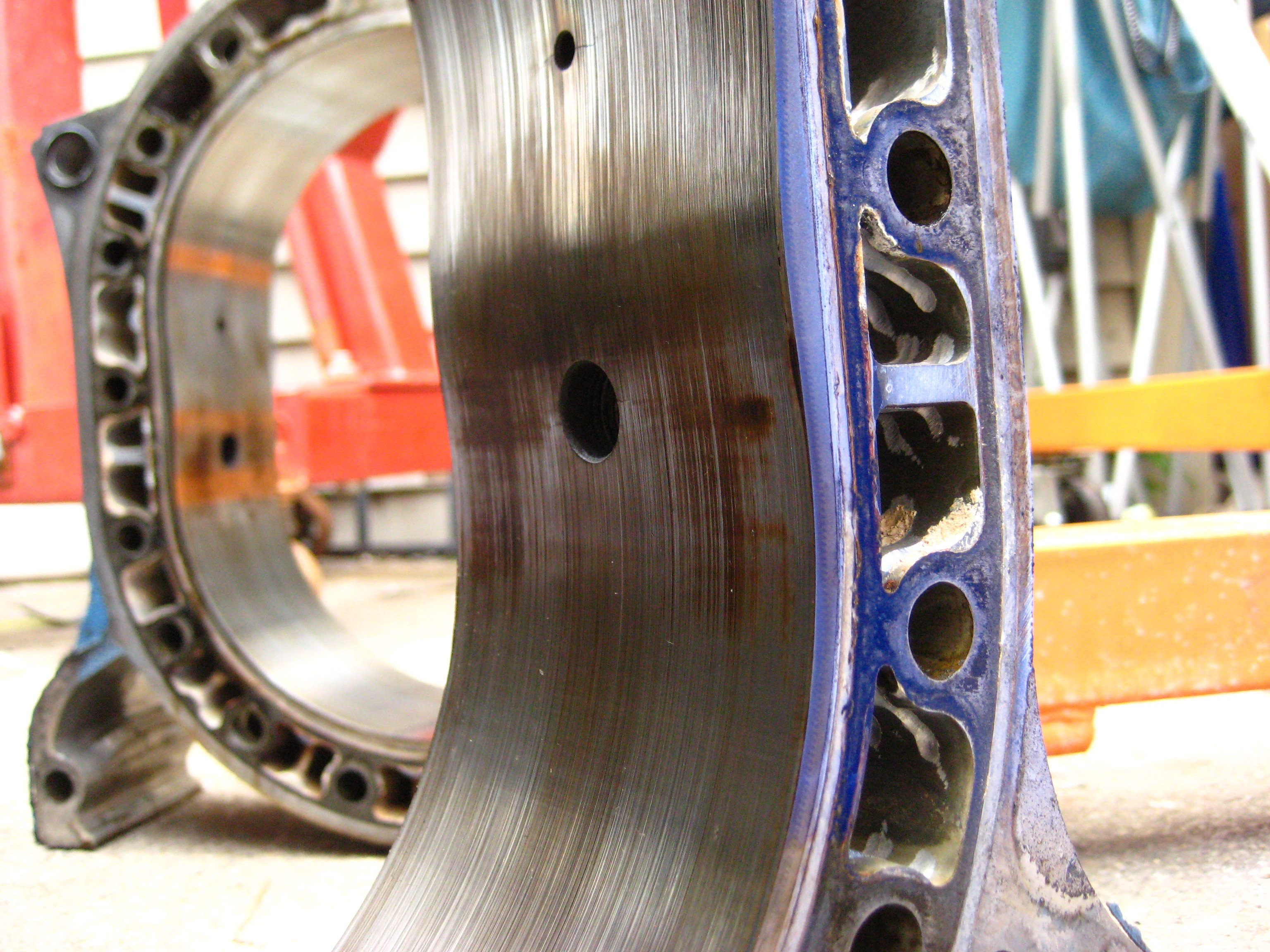

Once like this the Chrome plate is MOLESTED! and the housing can go into the BIN!

Re grinding exposes the steel sleeve, SOLUTION? Do not use INFERIOR APEX SEALS.

Why pay money to the these people with their 'fence post' quality material seals with ZERO ENGINEERING behind them, sure it may be used in a chrome sticker wearing cars

that lasts for less than a minute in total?........... but you will be disappointed, use more oil that an Arab Oil Well can produce trying to keep them from molesting your rotor housings as per

below. None of these wannabe's know anything about steel, or engineering longevity into ALL components, they ONLY know how to buy cheap materials that will molest your rotor housings, wear

out, and bend like a BANANA OR SNAP INTO MULTIPLE PIECES!........... and you were/are insulted by these people and their excuses for all these years to accept this as a normal condition of operation?????

WELL NOW THERE IS A REAL ENGINEERING ALTERNATIVE, no compromise, no excuses, no caveats, no 'each situation is unique', this is why your housings got raped despite throwing more oil at it than

an anal cavity in a porn movie.

***** ALL RUN PER THEIR 'monkey magic' RECOMMENDATIONS***** ***** ALL RUN PER THEIR 'monkey magic' RECOMMENDATIONS*****

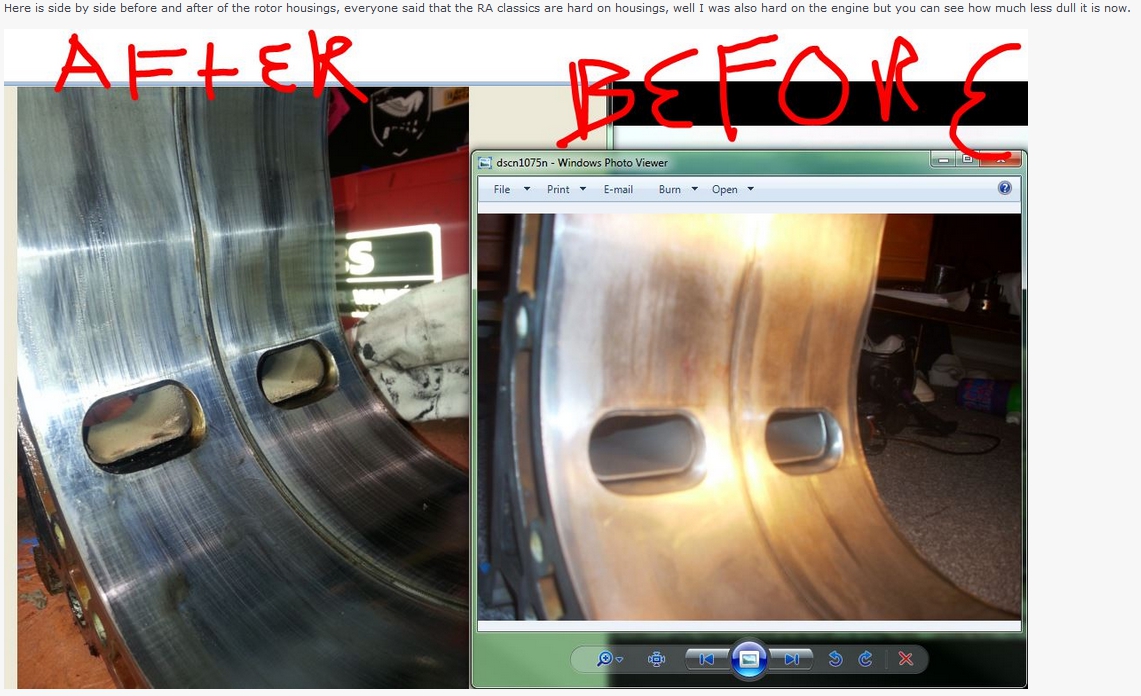

***These housings were all brand new and only done break in period then pulled apart to examine competitors paper hype claims..............

THANKS FOR THE RAPE!

Kiss good buy to the RAPE! of others poorly thought out products and 'guess work'

INFERIOR SEALS INFERIOR SEALS

WOW ! Look at this for an abortion! wrong material, poorly made, complete and utter molestation of seal and engine!!! This is what happens when you let chumps make things

STOP THE MADNESS!

QUOTE: RAPE VICTIM

"Oh yeah we did huh? lol

I was using ALS seals also. My exhaust ports were rectangular and the ends of the apex seals wore down as they went over the sides of the ports, while the middle did not. They wore down to the point that I lost compression enough to start the car. Oil and pull starting were the only ways to start it. I sent the seals back to Edgar and he said he was surprised it ran as long as it did considering the wear the housings put on the seals. He gave me a discount on another set of seals and I got a replacement engine so we'll see how this one does lol. This time I'm using ALS (or rather E&J) seals again, and the Pineapple HD kit and the rest is Atkins with their solid corner seals. Although I'm thinking I maybe should go with OEM corner seals this time. I had some chatter marks in my housings too. I was also thinking about using Goopy 1pc seals and using these E&J seals in another engine I'm going to build as a backup, but I'm not sure. "

Another RAPE VICTIM below........... different dog shit product, same end result! TOTAL MOLESTATION!

|

Summernats winner Capella with another FAILED BHP steel seal "wonder product" can smash it in a vice with hammer but that does not equal durability in an engine LOL ! sub 60 psi compression

Next is a Mazda OEM seal, last much longer than the *wonder hammer smashable in vice heap of dog turd* but still = EPIC FAIL in long term durability testing ! 60 psi compression!

Yet another failure of a 3rd "amazing" steel product, so have vice, CNC, hacksaw, wire cutter and glossy web page promise written on toilet paper = well you know what you wipe you're rear end with :)

Carbon seal = rooted ! taper wear, chewed ends, bad wear on leading edge = very low power...

Apex Seals, The good the bad the UGLY, real facts with zero hype.

Apex Seals, The good the bad the UGLY, real facts with zero hype.

When you pay peanuts you get this made by MONKEYS!

When you pay peanuts you get this made by MONKEYS!

ka-POW!

ka-POW!